A new publication written by the group on custom sensing equipment was recently published in the Journal of Instrumentation.

Abstract

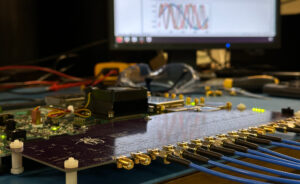

Novel electronic devices can often be operated in a plethora of ways, which makes testing circuits comprised of them difficult. Often, no single tool can simultaneously analyze the operating margins, maximum speed, and failure modes of a circuit, particularly when the intended behavior of subcomponents of the circuit is not standardized. This work demonstrates a cost-effective time-domain data acquisition system for electronic circuits that enables more intricate verification techniques than are practical with conventional experimental setups. We use high-speed digital-to-analog converters and real-time multi-gigasample-per-second waveform processing to push experimental circuits beyond their maximum operating speed. Our custom time-tagging data capture firmware reduces memory requirements and can be used to determine when errors occur. The firmware is combined with a thermal-noise-limited analog frontend with 50 dB of dynamic range. Compared to currently available commercial test equipment that is seven times more expensive, this data acquisition system was able to operate a superconducting shift register at a nearly three-times-higher clock frequency (200 MHz vs. 80 MHz).